Selecting an excellent wire and cable harness manufacturer is critical for contractors in various industries. However, with far too many companies producing harnesses for multiple applications, you must identify the one that best meets your needs. These include identifying manufacturers with the necessary experience, capabilities, and certifications to develop secure and efficient products that adhere to specific project requirements.

In this article, we will go over the qualities and qualifications of cable and wire harness manufacturers that you should consider to ensure that standards are met.

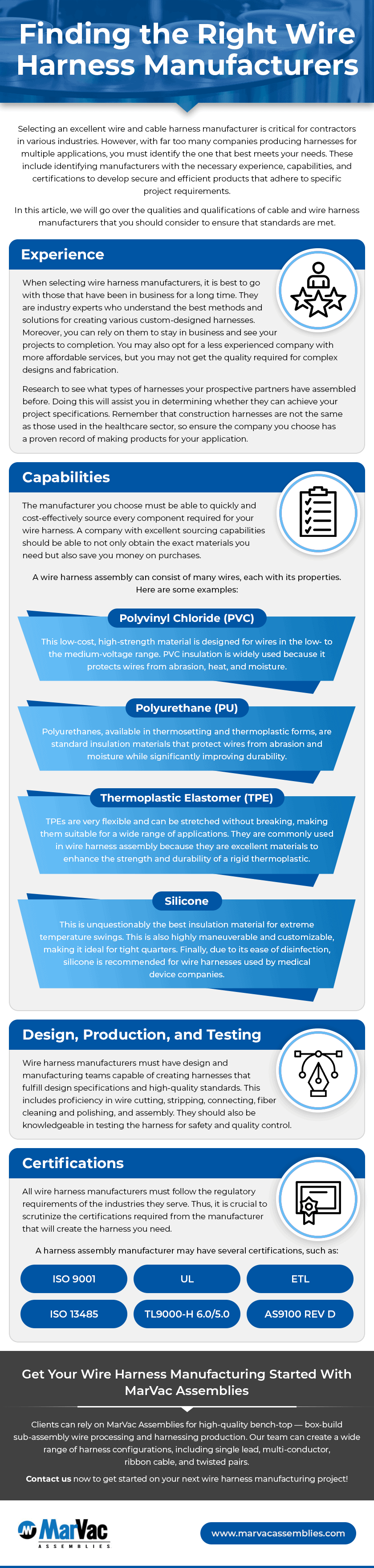

Experience

When selecting wire harness manufacturers, it is best to go with those that have been in business for a long time. They are industry experts who understand the best methods and solutions for creating various custom-designed harnesses. Moreover, you can rely on them to stay in business and see your projects to completion. You may also opt for a less experienced company with more affordable services, but you may not get the quality required for complex designs and fabrication.

Research to see what types of harnesses your prospective partners have assembled before. Doing this will assist you in determining whether they can achieve your project specifications. Remember that construction harnesses are not the same as those used in the healthcare sector, so ensure the company you choose has a proven record of making products for your application.

Capabilities

The manufacturer you choose must be able to quickly and cost-effectively source every component required for your wire harness. A company with excellent sourcing capabilities should be able to not only obtain the exact materials you need but also save you money on purchases.

A wire harness assembly can consist of many wires, each with its properties. Here are some examples:

Polyvinyl Chloride (PVC)

This low-cost, high-strength material is designed for wires in the low- to the medium-voltage range. PVC insulation is widely used because it protects wires from abrasion, heat, and moisture.

Polyurethane (PU)

Polyurethanes, available in thermosetting and thermoplastic forms, are standard insulation materials that protect wires from abrasion and moisture while significantly improving durability.

Thermoplastic Elastomer (TPE)

TPEs are very flexible and can be stretched without breaking, making them suitable for a wide range of applications. They are commonly used in wire harness assembly because they are excellent materials to enhance the strength and durability of a rigid thermoplastic.

Silicone

This is unquestionably the best insulation material for extreme temperature swings. This is also highly maneuverable and customizable, making it ideal for tight quarters. Finally, due to its ease of disinfection, silicone is recommended for wire harnesses used by medical device companies.

Design, Production, and Testing

Wire harness manufacturers must have design and manufacturing teams capable of creating harnesses that fulfill design specifications and high-quality standards. This includes proficiency in wire cutting, stripping, connecting, fiber cleaning and polishing, and assembly. They should also be knowledgeable in testing the harness for safety and quality control.

Certifications

All wire harness manufacturers must follow the regulatory requirements of the industries they serve. Thus, it is crucial to scrutinize the certifications required from the manufacturer that will create the harness you need.

A harness assembly manufacturer may have several certifications, such as:

- ISO 9001: This is an international standard for quality management systems (QMS).

- UL: Underwriters Laboratories, also known as UL, is a non-profit certification body acknowledged by the Occupational Safety and Health Administration (OSHA). This certification validates that the item meets all relevant safety and quality standards.

- ETL: Issued by Intertek’s Electrical Testing Labs, an OSHA-approved testing institution, this certification ensures that products fulfill stringent quality, safety, environmental, and social responsibility standards.

- ISO 13485: This indicates that a company has fulfilled the quality standards for medical cable assembly.

- TL9000-H 6.0/5.0: This certification proves that a company has met the requirements for telecommunications product quality.

- AS9100 REV D: This certification validates that a company has met requirements for producing quality aerospace products

Get Your Wire Harness Manufacturing Started With MarVac Assemblies

Clients can rely on MarVac Assemblies for high-quality bench-top — box-build sub-assembly wire processing and harnessing production. Our team can create a wide range of harness configurations, including single lead, multi-conductor, ribbon cable, and twisted pairs.

Contact us now to get started on your next wire harness manufacturing project!

1 Comment

Eugenedor

thanks, interesting read

_________________

https://BangladeshBookiestop.site