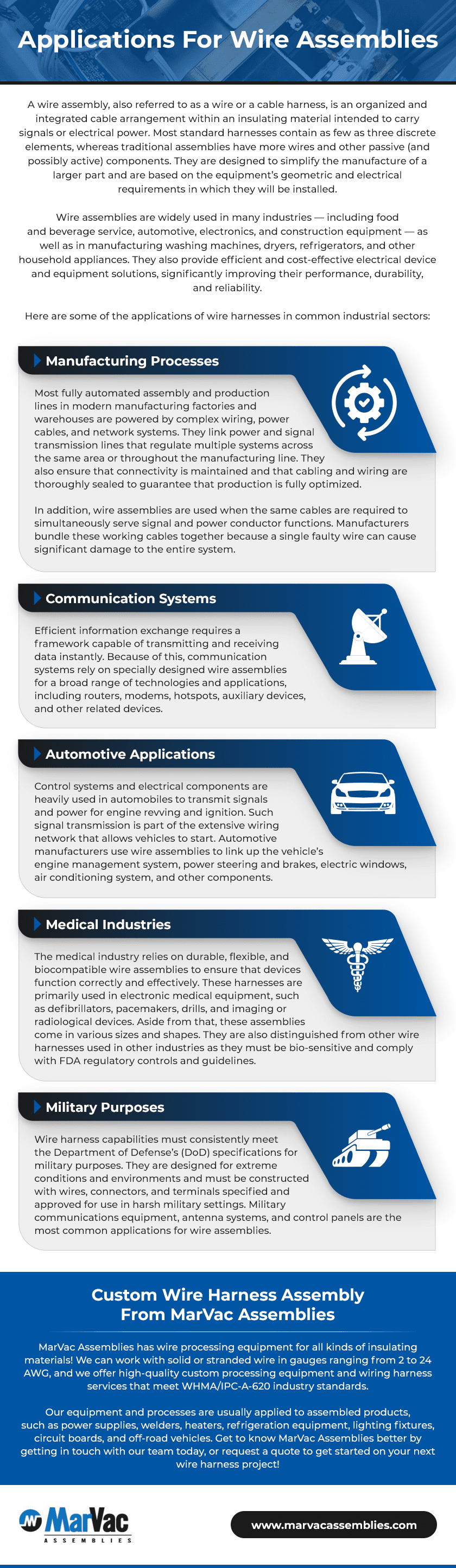

A wire assembly, also referred to as a wire or a cable harness, is an organized and integrated cable arrangement within an insulating material intended to carry signals or electrical power. Most standard harnesses contain as few as three discrete elements, whereas traditional assemblies have more wires and other passive (and possibly active) components. They are designed to simplify the manufacture of a larger part and are based on the equipment’s geometric and electrical requirements in which they will be installed.

Wire assemblies are widely used in many industries — including food and beverage service, automotive, electronics, and construction equipment — as well as in manufacturing washing machines, dryers, refrigerators, and other household appliances. They also provide efficient and cost-effective electrical device and equipment solutions, significantly improving their performance, durability, and reliability.

Here are some of the applications of wire harnesses in common industrial sectors:

Manufacturing Processes

Most fully automated assembly and production lines in modern manufacturing factories and warehouses are powered by complex wiring, power cables, and network systems. They link power and signal transmission lines that regulate multiple systems across the same area or throughout the manufacturing line. They also ensure that connectivity is maintained and that cabling and wiring are thoroughly sealed to guarantee that production is fully optimized.

In addition, wire assemblies are used when the same cables are required to simultaneously serve signal and power conductor functions. Manufacturers bundle these working cables together because a single faulty wire can cause significant damage to the entire system.

Communication Systems

Efficient information exchange requires a framework capable of transmitting and receiving data instantly. Because of this, communication systems rely on specially designed wire assemblies for a broad range of technologies and applications, including routers, modems, hotspots, auxiliary devices, and other related devices.

Automotive Applications

Control systems and electrical components are heavily used in automobiles to transmit signals and power for engine revving and ignition. Such signal transmission is part of the extensive wiring network that allows vehicles to start. Automotive manufacturers use wire assemblies to link up the vehicle’s engine management system, power steering and brakes, electric windows, air conditioning system, and other components.

Medical Industries

The medical industry relies on durable, flexible, and biocompatible wire assemblies to ensure that devices function correctly and effectively. These harnesses are primarily used in electronic medical equipment, such as defibrillators, pacemakers, drills, and imaging or radiological devices. Aside from that, these assemblies come in various sizes and shapes. They are also distinguished from other wire harnesses used in other industries as they must be bio-sensitive and comply with FDA regulatory controls and guidelines.

Military Purposes

Wire harness capabilities must consistently meet the Department of Defense’s (DoD) specifications for military purposes. They are designed for extreme conditions and environments and must be constructed with wires, connectors, and terminals specified and approved for use in harsh military settings. Military communications equipment, antenna systems, and control panels are the most common applications for wire assemblies.

Custom Wire Harness Assembly From MarVac Assemblies

MarVac Assemblies has wire processing equipment for all kinds of insulating materials! We can work with solid or stranded wire in gauges ranging from 2 to 24 AWG, and we offer high-quality custom processing equipment and wiring harness services that meet WHMA/IPC-A-620 industry standards.

Our equipment and processes are usually applied to assembled products, such as power supplies, welders, heaters, refrigeration equipment, lighting fixtures, circuit boards, and off-road vehicles. Get to know MarVac Assemblies better by getting in touch with our team today, or request a quote to get started on your next wire harness project!