Finding the Right Wire Harness Manufacturers

1 CommentSelecting an excellent wire and cable harness manufacturer is critical for contractors in various industries. However, with far too many companies producing harnesses for multiple applications, you must identify the one that best meets your needs. These include identifying manufacturers with the necessary experience, capabilities, and certifications to develop secure and efficient products that adhere to specific project requirements.

In this article, we will go over the qualities and qualifications of cable and wire harness manufacturers that you should consider to ensure that standards are met.

Experience

When selecting wire harness manufacturers, it is best to go with those that have been in business for a long time. They are industry experts who understand the best methods and solutions for creating various custom-designed harnesses. Moreover, you can rely on them to stay in business and see your projects to completion. You may also opt for a less experienced company with more affordable services, but you may not get the quality required for complex designs and fabrication.

Research to see what types of harnesses your prospective partners have assembled before. Doing this will assist you in determining whether they can achieve your project specifications. Remember that construction harnesses are not the same as those used in the healthcare sector, so ensure the company you choose has a proven record of making products for your application.

Capabilities

The manufacturer you choose must be able to quickly and cost-effectively source every component required for your wire harness. A company with excellent sourcing capabilities should be able to not only obtain the exact materials you need but also save you money on purchases.

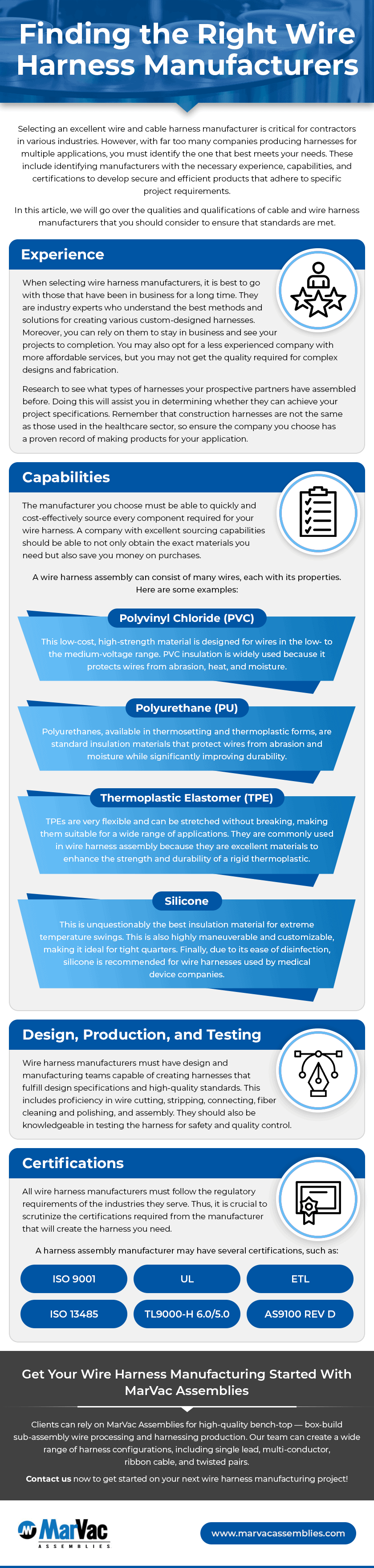

A wire harness assembly can consist of many wires, each with its properties. Here are some examples:

Polyvinyl Chloride (PVC)

This low-cost, high-strength material is designed for wires in the low- to the medium-voltage range. PVC insulation is widely used because it protects wires from abrasion, heat, and moisture.

Polyurethane (PU)

Polyurethanes, available in thermosetting and thermoplastic forms, are standard insulation materials that protect wires from abrasion and moisture while significantly improving durability.

Thermoplastic Elastomer (TPE)

TPEs are very flexible and can be stretched without breaking, making them suitable for a wide range of applications. They are commonly used in wire harness assembly because they are excellent materials to enhance the strength and durability of a rigid thermoplastic.

Silicone

This is unquestionably the best insulation material for extreme temperature swings. This is also highly maneuverable and customizable, making it ideal for tight quarters. Finally, due to its ease of disinfection, silicone is recommended for wire harnesses used by medical device companies.

Design, Production, and Testing

Wire harness manufacturers must have design and manufacturing teams capable of creating harnesses that fulfill design specifications and high-quality standards. This includes proficiency in wire cutting, stripping, connecting, fiber cleaning and polishing, and assembly. They should also be knowledgeable in testing the harness for safety and quality control.

Certifications

All wire harness manufacturers must follow the regulatory requirements of the industries they serve. Thus, it is crucial to scrutinize the certifications required from the manufacturer that will create the harness you need.

A harness assembly manufacturer may have several certifications, such as:

- ISO 9001: This is an international standard for quality management systems (QMS).

- UL: Underwriters Laboratories, also known as UL, is a non-profit certification body acknowledged by the Occupational Safety and Health Administration (OSHA). This certification validates that the item meets all relevant safety and quality standards.

- ETL: Issued by Intertek’s Electrical Testing Labs, an OSHA-approved testing institution, this certification ensures that products fulfill stringent quality, safety, environmental, and social responsibility standards.

- ISO 13485: This indicates that a company has fulfilled the quality standards for medical cable assembly.

- TL9000-H 6.0/5.0: This certification proves that a company has met the requirements for telecommunications product quality.

- AS9100 REV D: This certification validates that a company has met requirements for producing quality aerospace products

Get Your Wire Harness Manufacturing Started With MarVac Assemblies

Clients can rely on MarVac Assemblies for high-quality bench-top — box-build sub-assembly wire processing and harnessing production. Our team can create a wide range of harness configurations, including single lead, multi-conductor, ribbon cable, and twisted pairs.

Contact us now to get started on your next wire harness manufacturing project!

Applications for Wire Assemblies

Leave a CommentA wire assembly, also referred to as a wire or a cable harness, is an organized and integrated cable arrangement within an insulating material intended to carry signals or electrical power. Most standard harnesses contain as few as three discrete elements, whereas traditional assemblies have more wires and other passive (and possibly active) components. They are designed to simplify the manufacture of a larger part and are based on the equipment’s geometric and electrical requirements in which they will be installed.

Wire assemblies are widely used in many industries — including food and beverage service, automotive, electronics, and construction equipment — as well as in manufacturing washing machines, dryers, refrigerators, and other household appliances. They also provide efficient and cost-effective electrical device and equipment solutions, significantly improving their performance, durability, and reliability.

Here are some of the applications of wire harnesses in common industrial sectors:

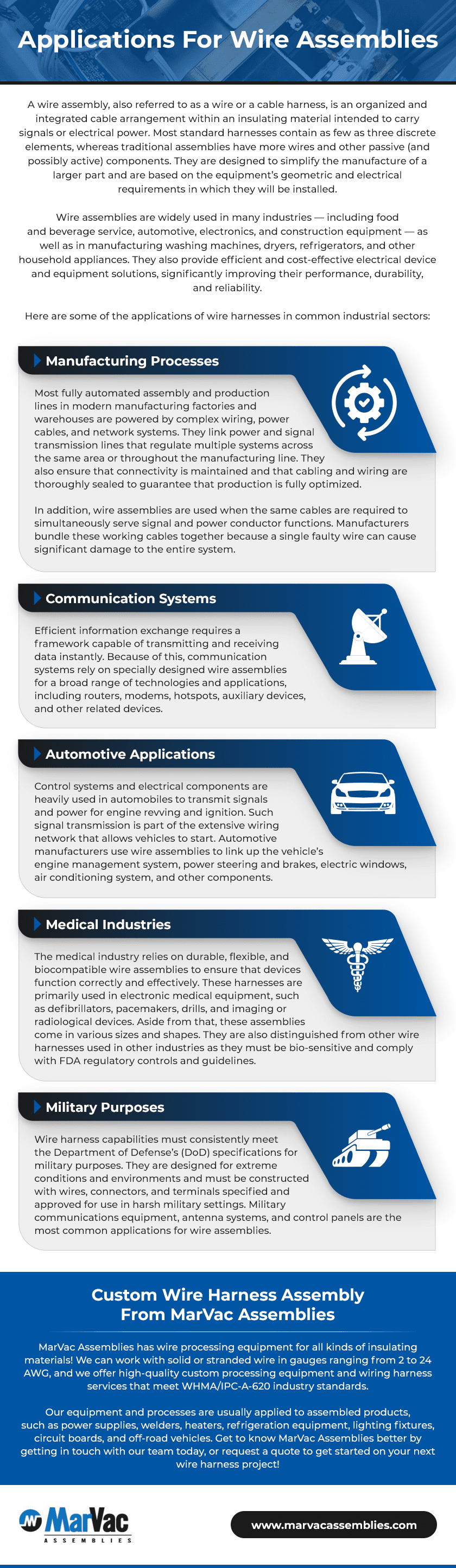

Manufacturing Processes

Most fully automated assembly and production lines in modern manufacturing factories and warehouses are powered by complex wiring, power cables, and network systems. They link power and signal transmission lines that regulate multiple systems across the same area or throughout the manufacturing line. They also ensure that connectivity is maintained and that cabling and wiring are thoroughly sealed to guarantee that production is fully optimized.

In addition, wire assemblies are used when the same cables are required to simultaneously serve signal and power conductor functions. Manufacturers bundle these working cables together because a single faulty wire can cause significant damage to the entire system.

Communication Systems

Efficient information exchange requires a framework capable of transmitting and receiving data instantly. Because of this, communication systems rely on specially designed wire assemblies for a broad range of technologies and applications, including routers, modems, hotspots, auxiliary devices, and other related devices.

Automotive Applications

Control systems and electrical components are heavily used in automobiles to transmit signals and power for engine revving and ignition. Such signal transmission is part of the extensive wiring network that allows vehicles to start. Automotive manufacturers use wire assemblies to link up the vehicle’s engine management system, power steering and brakes, electric windows, air conditioning system, and other components.

Medical Industries

The medical industry relies on durable, flexible, and biocompatible wire assemblies to ensure that devices function correctly and effectively. These harnesses are primarily used in electronic medical equipment, such as defibrillators, pacemakers, drills, and imaging or radiological devices. Aside from that, these assemblies come in various sizes and shapes. They are also distinguished from other wire harnesses used in other industries as they must be bio-sensitive and comply with FDA regulatory controls and guidelines.

Military Purposes

Wire harness capabilities must consistently meet the Department of Defense’s (DoD) specifications for military purposes. They are designed for extreme conditions and environments and must be constructed with wires, connectors, and terminals specified and approved for use in harsh military settings. Military communications equipment, antenna systems, and control panels are the most common applications for wire assemblies.

Custom Wire Harness Assembly From MarVac Assemblies

MarVac Assemblies has wire processing equipment for all kinds of insulating materials! We can work with solid or stranded wire in gauges ranging from 2 to 24 AWG, and we offer high-quality custom processing equipment and wiring harness services that meet WHMA/IPC-A-620 industry standards.

Our equipment and processes are usually applied to assembled products, such as power supplies, welders, heaters, refrigeration equipment, lighting fixtures, circuit boards, and off-road vehicles. Get to know MarVac Assemblies better by getting in touch with our team today, or request a quote to get started on your next wire harness project!

Understanding Custom Wiring Harness Manufacturing Capabilities

1 CommentA wire harness is a collective term for a systematic set of wires organized together with terminals and connectors within a thermoplastic insulating material. Generally, these devices protect and organize wires, making them safer and easy to navigate simultaneously.

This article will discuss the importance of wire harnesses, the processes involved in custom wiring harness manufacturing, and their value to different industries.

Importance of Wire Harnesses in Electronics

Wire harnesses are crucial components of electronics. It serves as the backbone of digital parts, allowing the transmission of electronic signals from one point to another. Instead of multiple cables running in a parallel circuit, wire harnesses provide a safer option featuring a centralized connection.

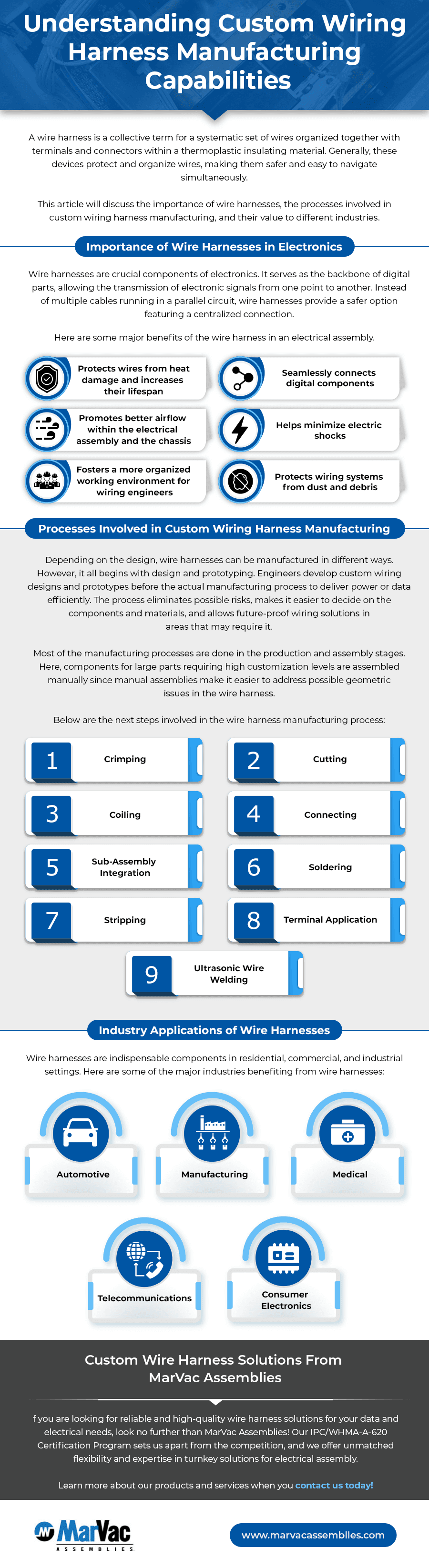

Here are some major benefits of the wire harness in an electrical assembly.

- Protects wires from heat damage and increases their lifespan

- Seamlessly connects digital components

- Promotes better airflow within the electrical assembly and the chassis

- Helps minimize electric shocks

- Fosters a more organized working environment for wiring engineers

- Protects wiring systems from dust and debris

Processes Involved in Custom Wiring Harness Manufacturing

Depending on the design, wire harnesses can be manufactured in different ways. However, it all begins with design and prototyping. Engineers develop custom wiring designs and prototypes before the actual manufacturing process to deliver power or data efficiently. The process eliminates possible risks, makes it easier to decide on the components and materials, and allows future-proof wiring solutions in areas that may require it.

Most of the manufacturing processes are done in the production and assembly stages. Here, components for large parts requiring high customization levels are assembled manually since manual assemblies make it easier to address possible geometric issues in the wire harness.

Below are the next steps involved in the wire harness manufacturing process:

Crimping

Crimping is a necessary manufacturing process in wire harness production. It is the process of joining pieces of metal by deforming one or both components to hold each other inside the harness. The process allows connecting a terminal to a wire conductor without having to undergo soldering, reducing the risk of corrosion.

Cutting

In this step, wires are cut to size depending on the initial design or prototype of the wire harness assembly. A wire-cutting machine is utilized to standardize the process.

Coiling

Coiling makes it possible to keep long wires together and intact. It also aids in minimizing stress on the wire by providing allowances for movement, such as bending and stretching.

Connecting

Inserting the wire into the connector after crimping contacts to the end of the wire is part of the connecting process.

Sub-Assembly Integration

In the sub-assembly stage, build components are integrated into different component assemblies to create a large segment of the final product. Manufacturing sub-assemblies makes it easier to assemble the final product, which saves time and resources for OEMs.

Soldering

Soldering is joining different wires and sub-assemblies with a metal alloy to create a larger end product or component.

Stripping

Removing the outer protective sheet of the wire harness without cutting the components beneath describes the stripping process. Stripping enables the electrician to expose the wire to create new connections or to do repairs.

Terminal Application

In the terminal application, the wire harness is connected to the junction connector, which functions as a wire connector. The terminal serves as the connection between the plug and the wire. In the automotive industry, terminal crimping is the link in the production process of automotive wire harnesses.

Ultrasonic Wire Welding

Ultrasonic wire welding is the technology used in creating wire harnesses in different industries and is the ideal welding type for connecting plastics and metals. It is the process of combining multiple wires to a terminal or conductive contact material. The connection is achieved with high-frequency ultrasonic vibrations applied to the components to create a solid weld.

Industry Applications of Wire Harnesses

Wire harnesses are indispensable components in residential, commercial, and industrial settings. Here are some of the major industries benefiting from wire harnesses:

Automotive

Wire harnesses enable transmitting signals and commands from the main terminal to power up engines. They also connect the engine to the vehicle’s other functions, such as brakes, audio, HVAC, and lighting.

Manufacturing

Wire harnesses connect a device to its power and signal system to allow it to function and perform efficiently.

Medical

Wire harnesses protect wiring used in imaging, radiology, and pacemakers. These components are essential to keep these devices running optimally, preventing catastrophic medical or health problems.

Telecommunications

Telecommunications networks operate and communicate through wires protected and bolstered by wire harness technologies.

Consumer Electronics

Multiple wire harnesses are the backbone of all consumer electronic products. From small appliances to supercomputers, wire harnesses make it possible to transport data and power various gadgets and devices.

Custom Wire Harness Solutions From MarVac Assemblies

If you are looking for reliable and high-quality wire harness solutions for your data and electrical needs, look no further than MarVac Assemblies! Our IPC/WHMA-A-620 Certification Program sets us apart from the competition, and we offer unmatched flexibility and expertise in turnkey solutions for electrical assembly.

Learn more about our products and services when you contact us today!

Evaluating Capabilities of Custom Wire Harness Manufacturers

Leave a CommentCustom cable manufacturers have varying facility equipment and unique production and inspection procedures. Therefore, it is crucial to conduct thorough research and understand the benefits and characteristics of each manufacturer if you require specialized custom wire harnesses for your project. These include their manufacturing capabilities, production tools, quality assurance systems, certifications, and raw material suppliers.

Evaluating Custom Wire Harness Manufacturers

Cable wire harness assemblies consist of various cable types, including power cables, cable fiber optics, and data cables. Additionally, different assemblies call for distinct connectors, ferrules, terminal blocks, bushings, and other parts. Complex customized cable wire harnesses could also need extra tools for assembly demands in strain reliefs, transition zones, or splicing or over molding of the connectors.

All of this implies that the wire harness manufacturer you select should be able to swiftly and effectively obtain every component required for your assembly. In addition to finding the exact components you require, a business with strong sourcing capabilities should be able to help you save money on material purchases.

What To Look for in Custom Wire Harness Manufacturers

Choosing a cable harness manufacturer that has been in business for several years is ideal. These manufacturers are highly knowledgeable in their field and know the finest methods for building various intricate, specialized cable wire harnesses. Moreover, ensure that the manufacturer you choose has a proven track record in creating custom harnesses for your field.

Here are other considerations when researching custom wire harness manufacturers:

Customer Service Track Record

You should select a manufacturer that can offer significant advice and technical support to meet your expectations. Customer satisfaction-oriented service providers will also help you choose the best material for your application to increase your project’s cost-effectiveness and improve the overall quality of components.

Proven Capabilities in Your Industry

Cable applications and requirements vary per industry. You can ensure that you work with an experienced manufacturer and benefit your business by selecting a manufacturer specializing in custom cables for your industry. Ask them if they can give you the material to match the specifications of your industry.

Cable Requirements for Severe Environments

Although most cable wire manufacturer offers a lot of industry expertise and production experience, you must communicate your customized cable specifications to them. Suppose you require high-grade cables for complex wiring requirements for severe conditions. In that case, your manufacturer should be able to provide you with materials and manufacturing specifications that fit these requirements.

Custom Designs and Off-Shelf Cables

Ensure the cable manufacturer you choose specializes in creating custom items; otherwise, the final product may have issues if the manufacturer only typically deals with stock cable assemblies. It is important to have due diligence in learning about manufacturers’ work experience so that you can have appropriate quality and service expectations throughout the whole manufacturing process.

Certifications and Credentials

Look for certification, credentials, and other documentation that can verify the legitimacy and credibility of the custom wire harness manufacturers you are considering. Among the most common certificates in the cable wire manufacturing industry includes the following:

- ISO 9001

- UL Certification

- CE Certification

- ETF Certification

MarVac Assemblies for Certified and High-Quality Custom Wire Harness Solutions

MarVac Assemblies provide product specs, custom circuit recommendations, application research, and engineering concepts. Our team is ISO 9000:2015 certified, UL recognized, ESD Safe, and features certifications and compliances for RoHS Compliant Components and Soldering, WHMA/IPC A620, Hi-Pot Testing, and Continuity Testing.

We customize solutions based on your needs! Talk to us about your specific applications, and our experts will offer customized products and services that fit your budget and project timeline.

Contact us or request a quote to experience the MarVac Assemblies difference!