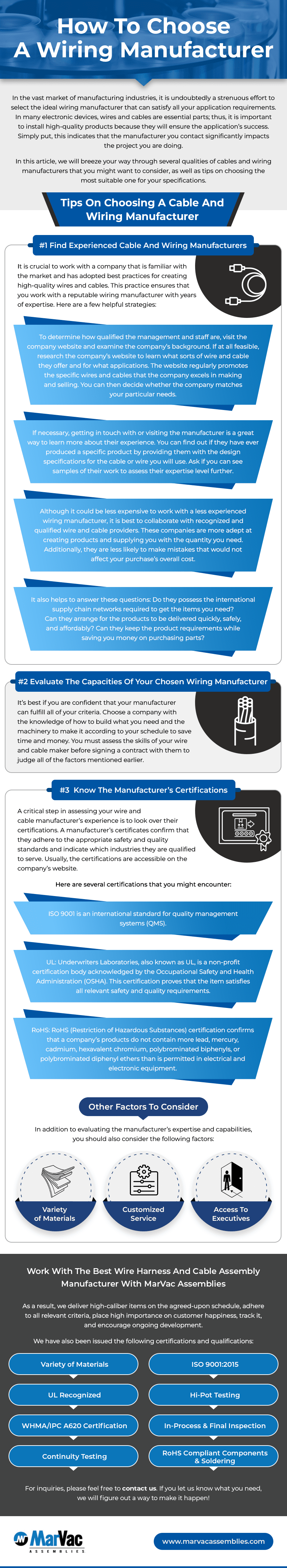

How To Choose A Wiring Manufacturer

1 CommentIn the vast market of manufacturing industries, it is undoubtedly a strenuous effort to select the ideal wiring manufacturer that can satisfy all your application requirements. In many electronic devices, wires and cables are essential parts; thus, it is important to install high-quality products because they will ensure the application’s success. Simply put, this indicates that the manufacturer you contact significantly impacts the project you are doing.

In this article, we will breeze your way through several qualities of cables and wiring manufacturers that you might want to consider, as well as tips on choosing the most suitable one for your specifications.

Tips On Choosing A Cable And Wiring Manufacturer

#1 – Find Experienced Cable And Wiring Manufacturers

It is crucial to work with a company that is familiar with the market and has adopted best practices for creating high-quality wires and cables. This practice ensures that you work with a reputable wiring manufacturer with years of expertise. Here are a few helpful strategies:

- To determine how qualified the management and staff are, visit the company website and examine the company’s background. If at all feasible, research the company’s website to learn what sorts of wire and cable they offer and for what applications. The website regularly promotes the specific wires and cables that the company excels in making and selling. You can then decide whether the company matches your particular needs.

- If necessary, getting in touch with or visiting the manufacturer is a great way to learn more about their experience. You can find out if they have ever produced a specific product by providing them with the design specifications for the cable or wire you will use. Ask if you can see samples of their work to assess their expertise level further.

- Although it could be less expensive to work with a less experienced wiring manufacturer, it is best to collaborate with recognized and qualified wire and cable providers. These companies are more adept at creating products and supplying you with the quantity you need. Additionally, they are less likely to make mistakes that would not affect your purchase’s overall cost.

- It also helps to answer these questions: Do they possess the international supply chain networks required to get the items you need? Can they arrange for the products to be delivered quickly, safely, and affordably? Can they keep the product requirements while saving you money on purchasing parts?

#2 – Evaluate The Capacities Of Your Chosen Wiring Manufacturer

It’s best if you are confident that your manufacturer can fulfill all of your criteria. Choose a company with the knowledge of how to build what you need and the machinery to make it according to your schedule to save time and money. You must assess the skills of your wire and cable maker before signing a contract with them to judge all of the factors mentioned earlier.

#3 – Know The Manufacturer’s Certifications

A critical step in assessing your wire and cable manufacturer’s experience is to look over their certifications. A manufacturer’s certificates confirm that they adhere to the appropriate safety and quality standards and indicate which industries they are qualified to serve. Usually, the certifications are accessible on the company’s website.

Here are several certifications that you might encounter:

- ETL: ETL certificates issued by Intertek’s Electrical Testing Labs, an OSHA-approved testing institution, ensure that products meet stringent quality, safety, environmental, and social responsibility standards.

- ISO 9001 is an international standard for quality management systems (QMS).

- UL: Underwriters Laboratories, also known as UL, is a non-profit certification body acknowledged by the Occupational Safety and Health Administration (OSHA). This certification proves that the item satisfies all relevant safety and quality requirements.

- ABS: American Bureau of Shipping or ABS certifies that the cables used in shipbuilding comply with the rules and regulations.

- RoHS: RoHS (Restriction of Hazardous Substances) certification confirms that a company’s products do not contain more lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, or polybrominated diphenyl ethers than is permitted in electrical and electronic equipment.

Other Factors To Consider

In addition to evaluating the manufacturer’s expertise and capabilities, you should also consider the following factors:

Variety Of Materials

The manufacturer must offer a diverse range of materials from which to choose. Regarding the various types of materials, consider these two questions: 1. Does the company offer both fiber optics and copper? 2. Does it have expertise with both cable types?

If this is the case, they are more likely to provide what you require, including making recommendations for using one type instead of the other for your application.

Customized Service

If you are looking for a smaller manufacturer, look for one that provides customized service. Customization improves perceived performance expectancy, customer satisfaction, integrity, and customer loyalty to the manufacturer.

Access To Executives

When problems arise, it is vital to make your voice heard. Ensure your wire and cable provider gives you immediate access to its executives to guarantee that you have the right audience if and when you need it.

Work With The Best Wire Harness And Cable Assembly Manufacturer With MarVac Assemblies

Making an informed decision regarding which wiring manufacturer will give you a high-quality product depends on the manufacturer’s experience, capacity, and certifications. MarVac Assemblies offers high-value customer solutions and application support for our client’s production and shipping processes. As a result, we deliver high-caliber items on the agreed-upon schedule, adhere to all relevant criteria, place high importance on customer happiness, track it, and encourage ongoing development.

We have also been issued the following certifications and qualifications:

- ESD Safe

- ISO 9001:2015

- RoHS Compliant Components and Soldering

- UL Recognized

- Hi-Pot Testing

- Continuity Testing

- WHMA/IPC A620 Certification

- In-Process and Final Inspection

For inquiries, please feel free to contact us. If you let us know what you need, we will figure out a way to make it happen!